CPC INOX

EVACUATED TUBE COLLECTORS

ABOUT THE COLLECTOR:

- For water heating and supplementary heating

- Can be connected in series

- Stainless steel heat pipes

SCOPE OF SUPPLIES:

The CPC collectors are supplied as fully preassembled units comprising:

- Evacuated tubes based on the thermos flask principle

- Manifold with direct flow heat conduction unit and dry tube connection

- CPC reflectors

The CPC OEM collectors are packed individually in cardboard boxes. To provide better protection for the products and installation personnel, the collectors are supplied with a sun protection foil over the evacuated tubes.

INSTALLATION TYPES:

- Roof installation

- Flat roof installation

Note: The manifold must always be installed upwards. The minimum angle for roof and flat roof installation is 15°.

| SERIES | CPC 6 INOX | CPC 12 INOX | CPC 18 INOX | |

| Number of evacuated tubes | 6 | 12 | 18 | |

| Collector energy output class (50°C/75°C) (Solergy) 1) | AA/AA | AA/AA | AA/AA | |

| Annual collector energy output (50 °C Würzburg) | kWh / Jahr | 665 | 1313 | 1961 |

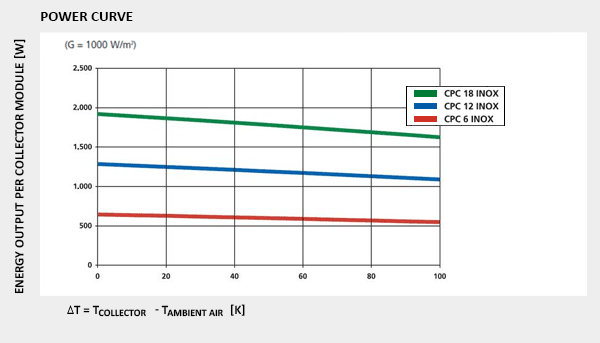

| Energy output per collector module 2) | W | 607 | 1198 | 1789 |

| Energy output per collector module 3) | W | 644 | 1272 | 1899 |

| Product data in accordance with the EU Regulations 811/2013 and 812/2013 (ErP-relevant data) collector reference area (gross) | ||||

| Asol collector reference area | m² | 1,16 | 2,29 | 3,42 |

| η0 zero-loss efficiency | 0,56 | 0,56 | 0,56 | |

| ηcol collector efficiency | % | 52 | 52 | 52 |

| a1 first-order heat transfer coefficient | W/(m² K) | 0,65 | 0,65 | 0,65 |

| a2 second-order heat transfer coefficient | W/(m² K²) | 0,004 | 0,004 | 0,004 |

| IAM incidence angle modifier | 0,99 | 0,99 | 0,99 | |

| more product detail | ||||

| Gross area | m² | 1,16 | 2,29 | 3,42 |

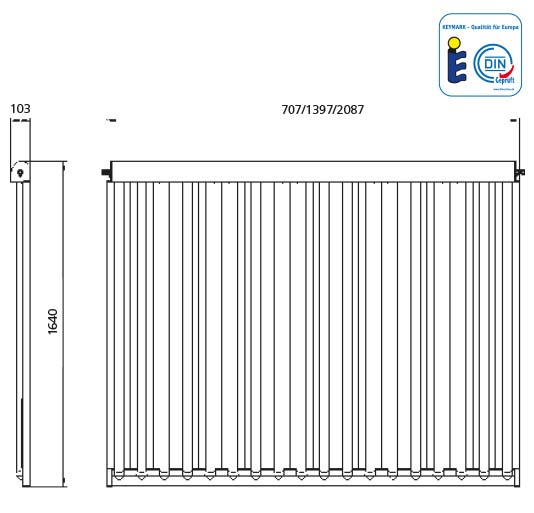

| Collector dimensions (length x width x height) | m | 1,64 x 0,71 x 0,10 | 1,64 x 1,40 x 0,10 | 1,64 x 2,09 x 0,10 |

| Collector contents | l | 0,87 | 1,73 | 2,60 |

| Weight of empty collector | kg | 17,4 | 32,7 | 48 |

| Max. admissible operating pressure | bar | 10 | 10 | 10 |

| Max. stagnation temperature | °C | 301 | 301 | 301 |

| Connection diameter, compression fitting | mm | 15 | 15 | 15 |

| Sensor sleeve | mm | 6 | 6 | 6 |

| Colour (aluminium frame section, anodized) | aluminum gray | |||

| Colour (plastic parts) | black | |||

| Conformity 4) | Pressure Equipment Directive 2014/68/EU | |||

| Impact resistance test in accordance with ISO 9806 | mm | 35 | ||

| Tests and approvals | ISO 9806, Solar Keymark | |||

| DIN-CERTCO registration number | 011-7S134 R | |||

1) Can be used only with own Solar Keymark certification, for details, refer to: www.solar-heating-initiative.com and www.dincertco.de/en/

2) At 1000 W/m² and 40 K temperature difference between the average collector temperature and ambient temperature.

3) BAt 1000 W/m² and 0 K temperature difference between the average collector temperature and ambient temperature.

4) Existing certification of collectors by TÜV SÜD Industrie Service GmbH for Ritter Energie- und Umwelttechnik GmbH & Co.KG; valid in Germany. TÜV can be contacted for separate certification in accordance with the Pressure Equipment Directive when needed.

2) At 1000 W/m² and 40 K temperature difference between the average collector temperature and ambient temperature.

3) BAt 1000 W/m² and 0 K temperature difference between the average collector temperature and ambient temperature.

4) Existing certification of collectors by TÜV SÜD Industrie Service GmbH for Ritter Energie- und Umwelttechnik GmbH & Co.KG; valid in Germany. TÜV can be contacted for separate certification in accordance with the Pressure Equipment Directive when needed.

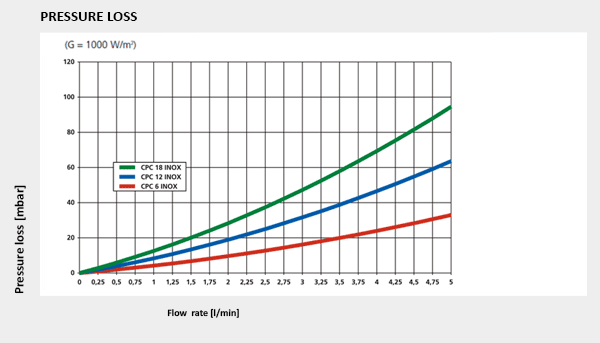

PRESSURE LOSS OF RITTER ENERGIE EVACUATED TUBE COLLECTORS CPC 6 INOX / 12 INOX /18 INOX

– heat transfer fluid: Tyfocor LS, fluid temperature 40°C

POWER CURVE OF RITTER ENERGIE EVACUATED TUBE COLLECTORS CPC 6 INOX / 12 INOX /18 INOX

– (G = 1000 W/m²)